The Fluid Sealing Technology Research Center has been committed to the research and application of friction mechanism and fluid sealing technology in industry for many years. The team of Fluid sealing Technology Research Center is composed of 7 teachers, 5 doctors and more than 30 masters. The team participated in the completion of a number of sealing research projects, more than 10 sealing related standards, accumulated a wealth of theoretical and practical engineering experience; And independently developed a variety of fluid seal calculation, analysis and design software; At the same time, a variety of test devices, control systems and measurement systems with complete functions have been built. At present, he has published more than 300 papers, of which more than 80 are included in SCI and EI. Applied for more than 50 national invention patents, more than 30 software Copyrights, and the employment rate of students is 100%.

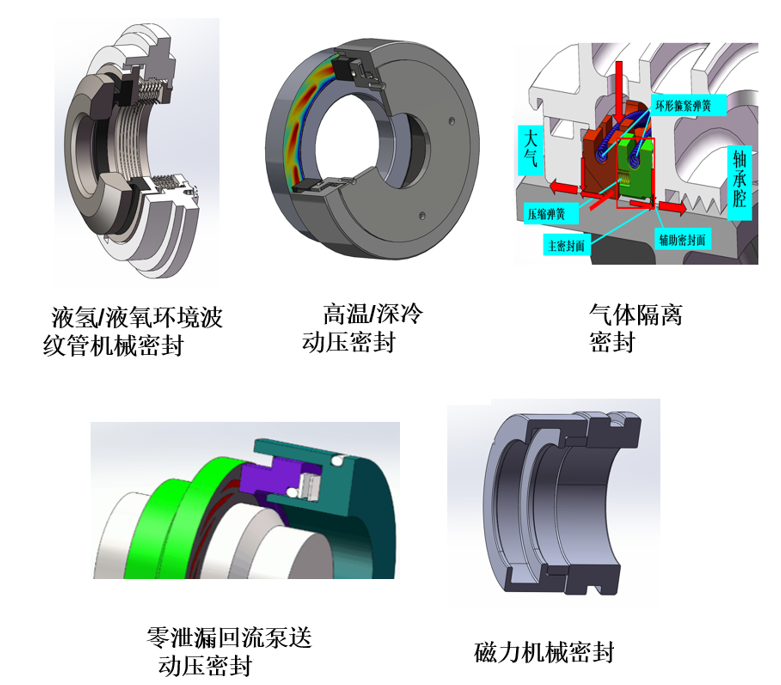

(1)Special fluid sealing technology

The research contents include the mechanism of thermoelastic micro-flow lubrication between the small clearance of the seal end face, the dynamic contact and wear evolution mechanism of the sealing interface materials under all working conditions, the vibration characteristics and vibration suppression methods of the face seal under complex flight attitude interference, and the research of the mechanical seal software platform and digital design based on multi-field coupling.

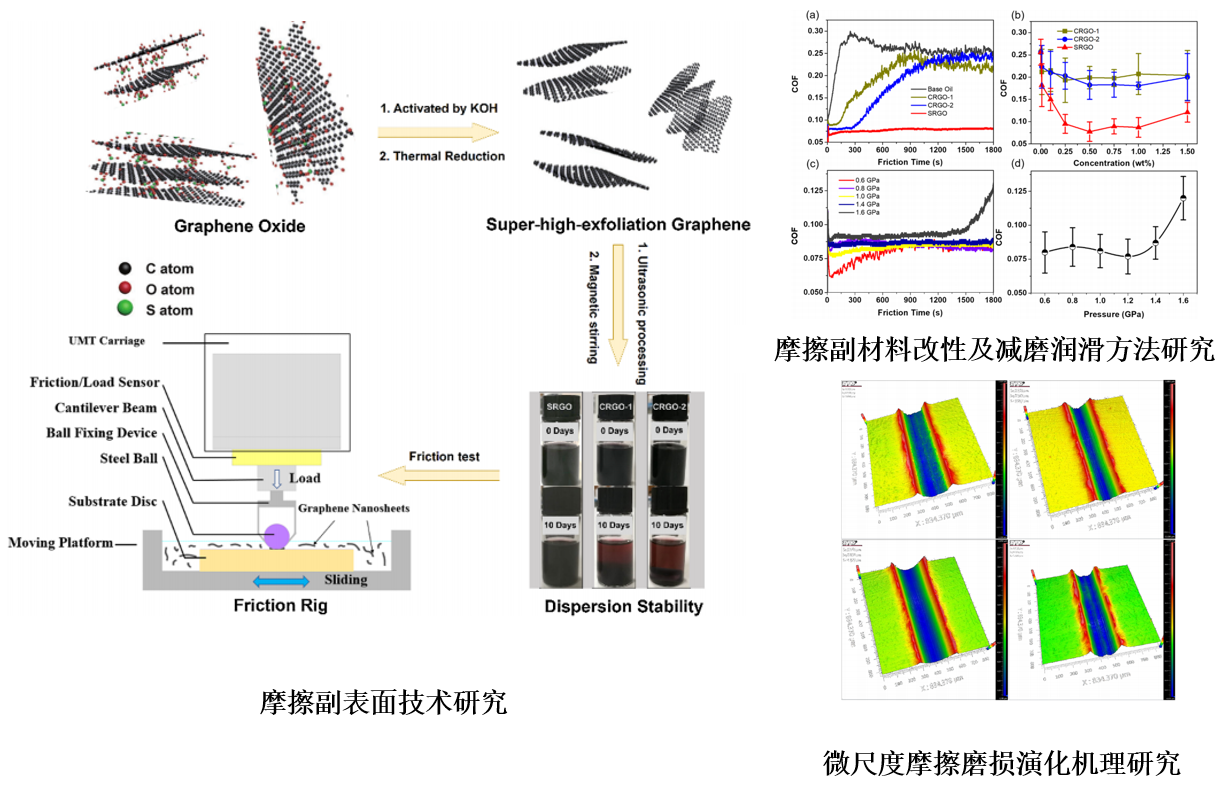

(2)Friction and Wear Lubrication Mechanism

The research contents include the research of material modification and matching technology of friction pair under high temperature and heavy load conditions, the research of anti-wear lubrication mechanism of surface micro-texture, and the research and application of ultra-precision shallow groove machining technology.

(3)Process equipment research and development

Research content includes solid hydrogen storage integrated unit technology research, high energy density and high reliability solid hydrogen storage system research and development, ultra-high pressure pressure vessel analysis and design.

|

|

四、Research Results

1. Aerospace Sealing Technology

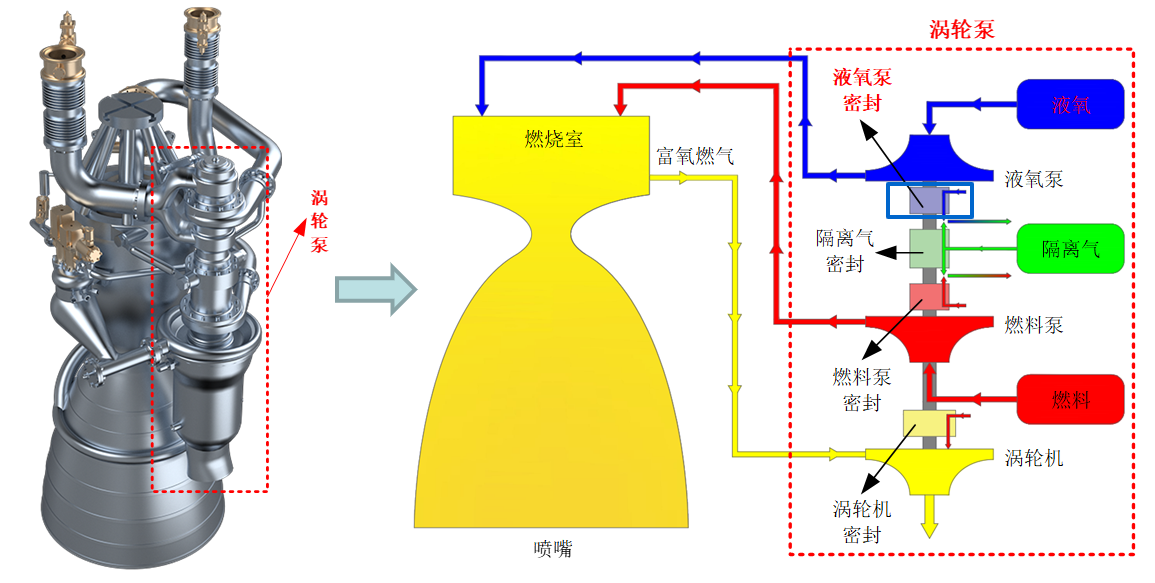

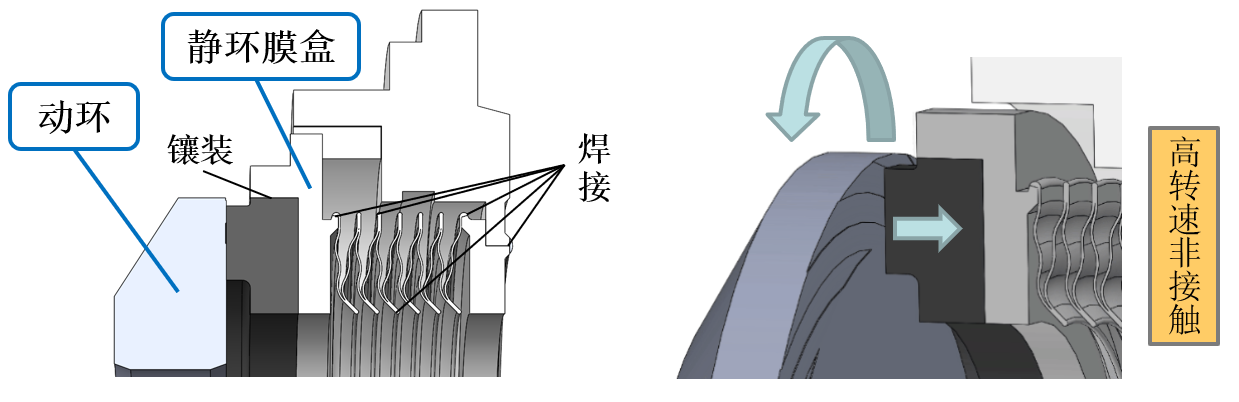

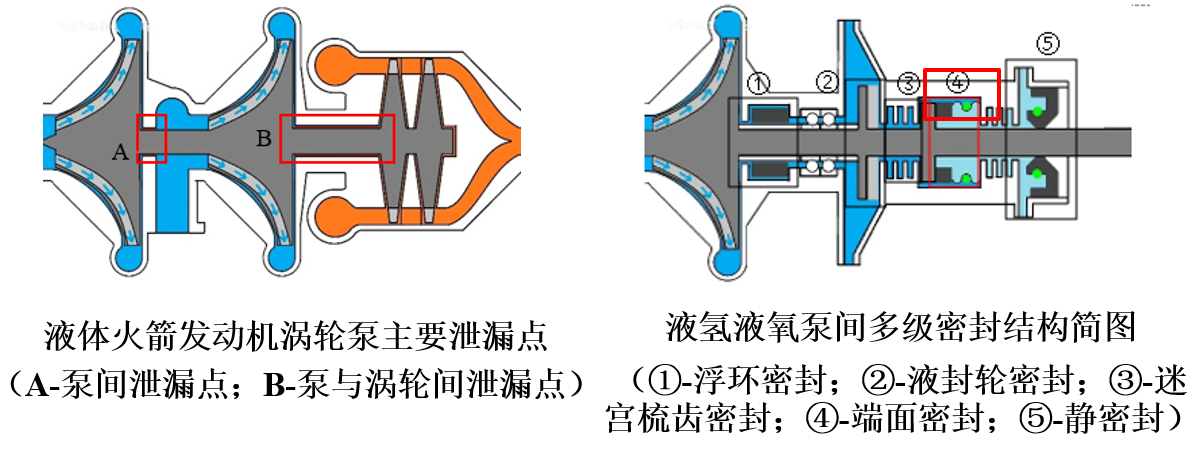

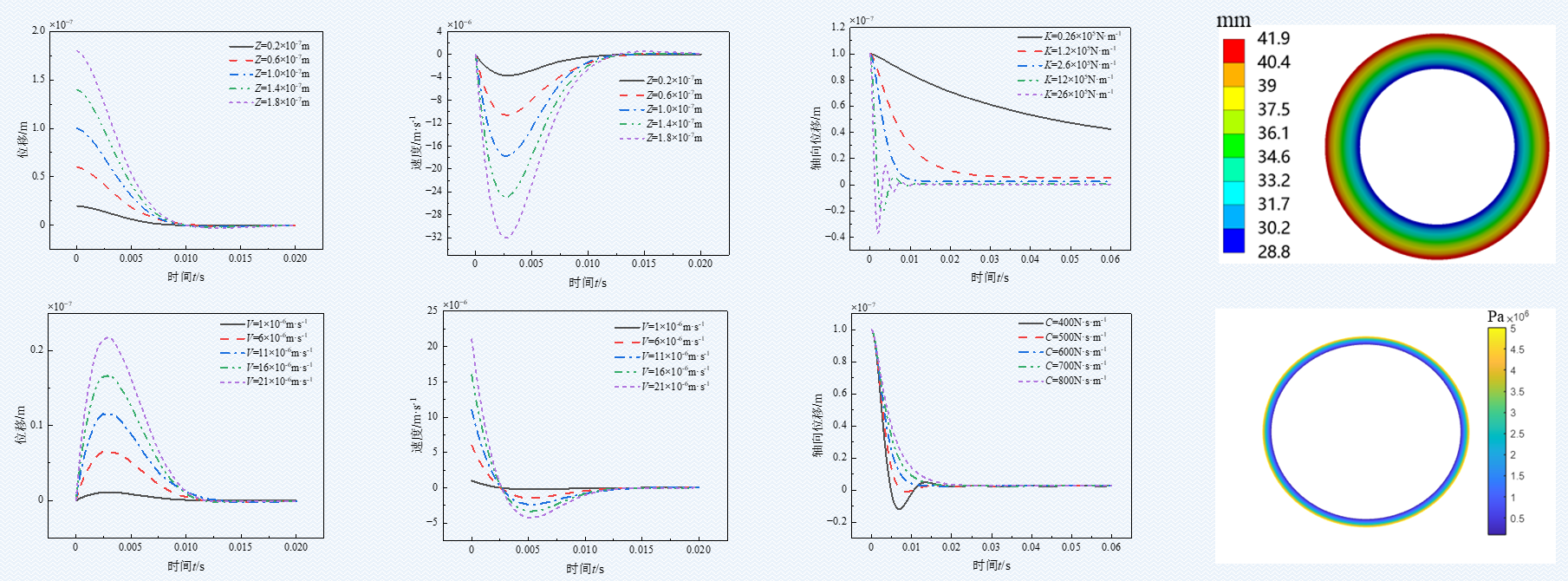

(1)Research on Dynamic Pressure Sealing Technology of Liquid Oxygen Turbopump

The dynamic pressure seal performance of bellows applied to liquid oxygen pump of liquid rocket engine was studied, and the structural design and optimization were guided to ensure the stable operation of seal in the whole working cycle. Improve the single operation time and the number of reusable seals; It can be applied in more severe conditions such as high speed, large pressure difference and deep cold medium environment.

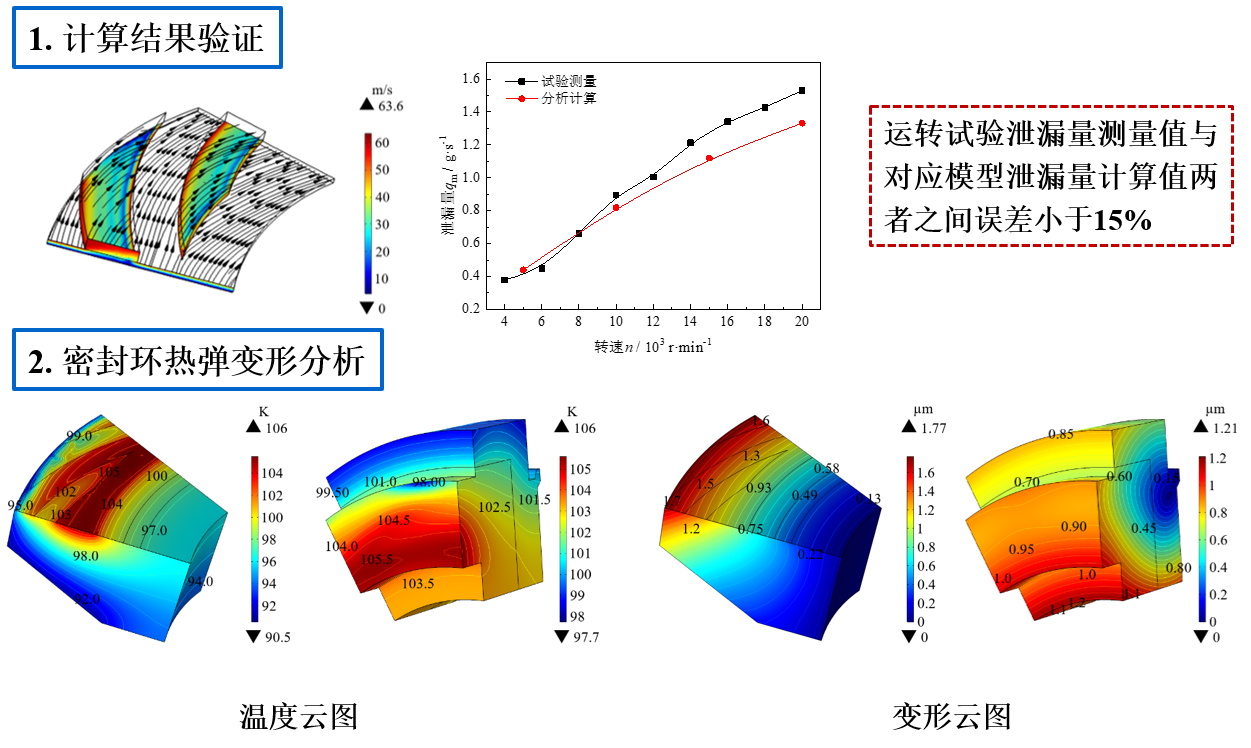

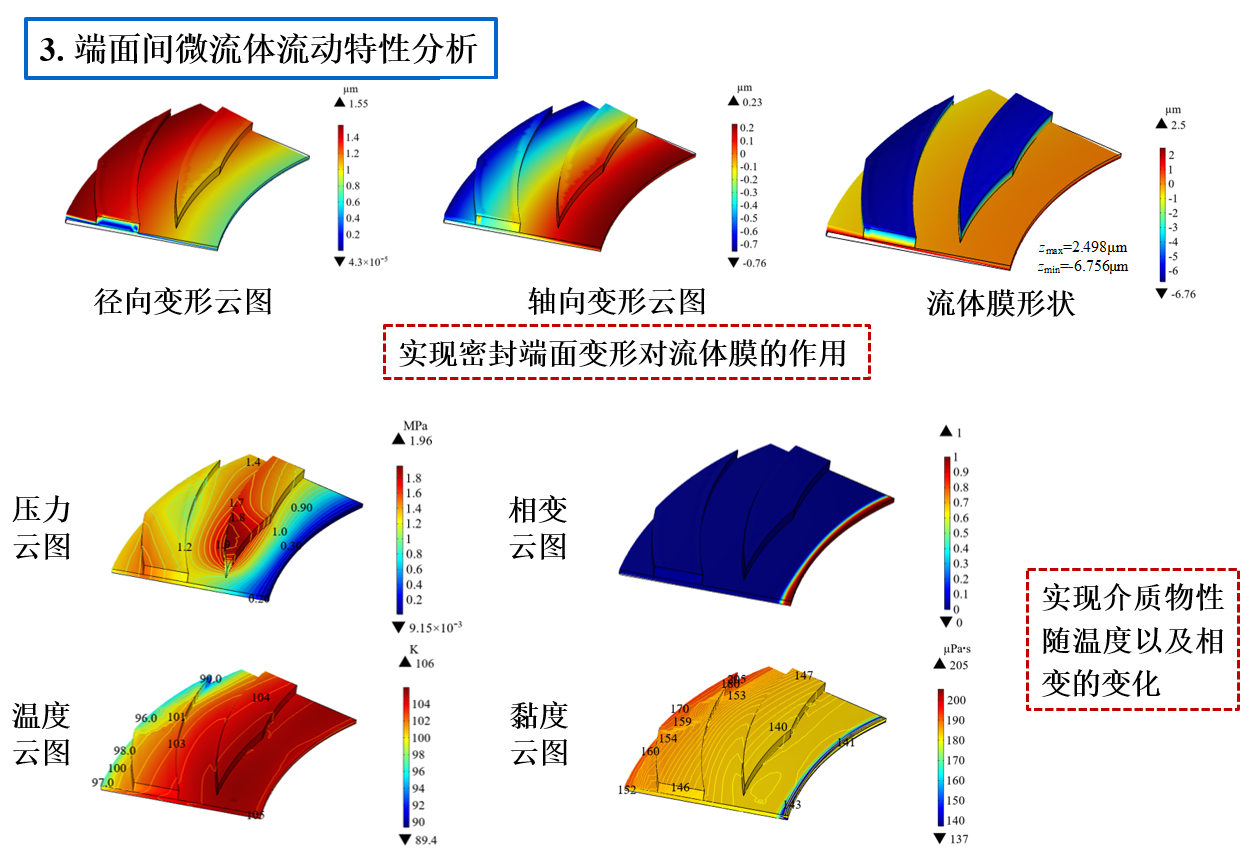

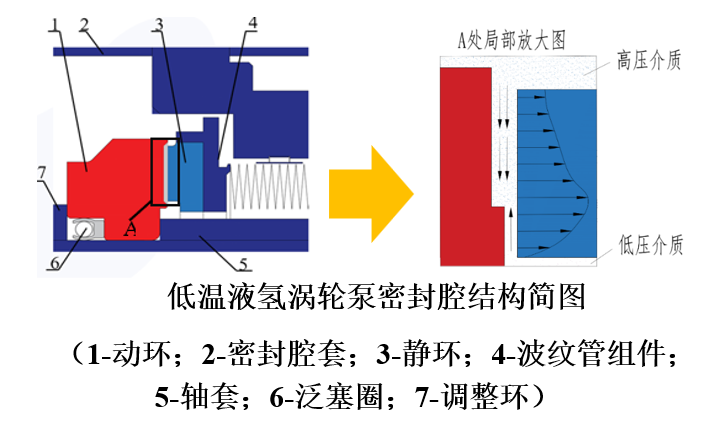

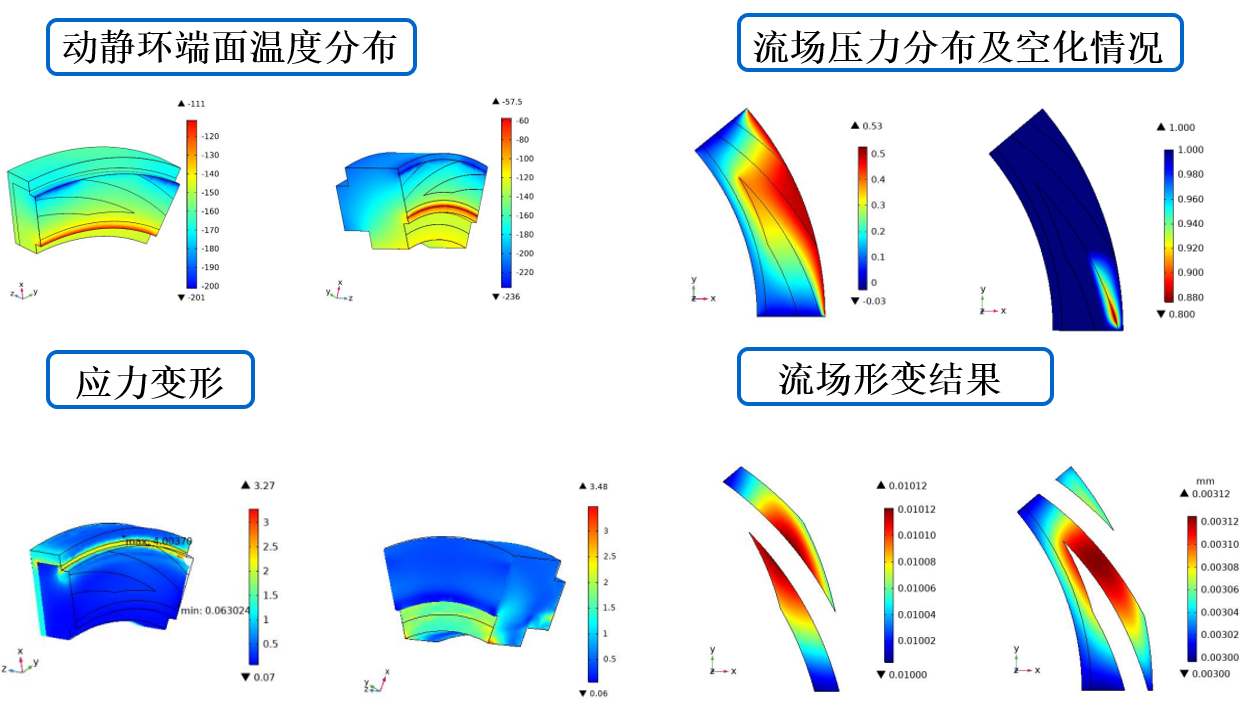

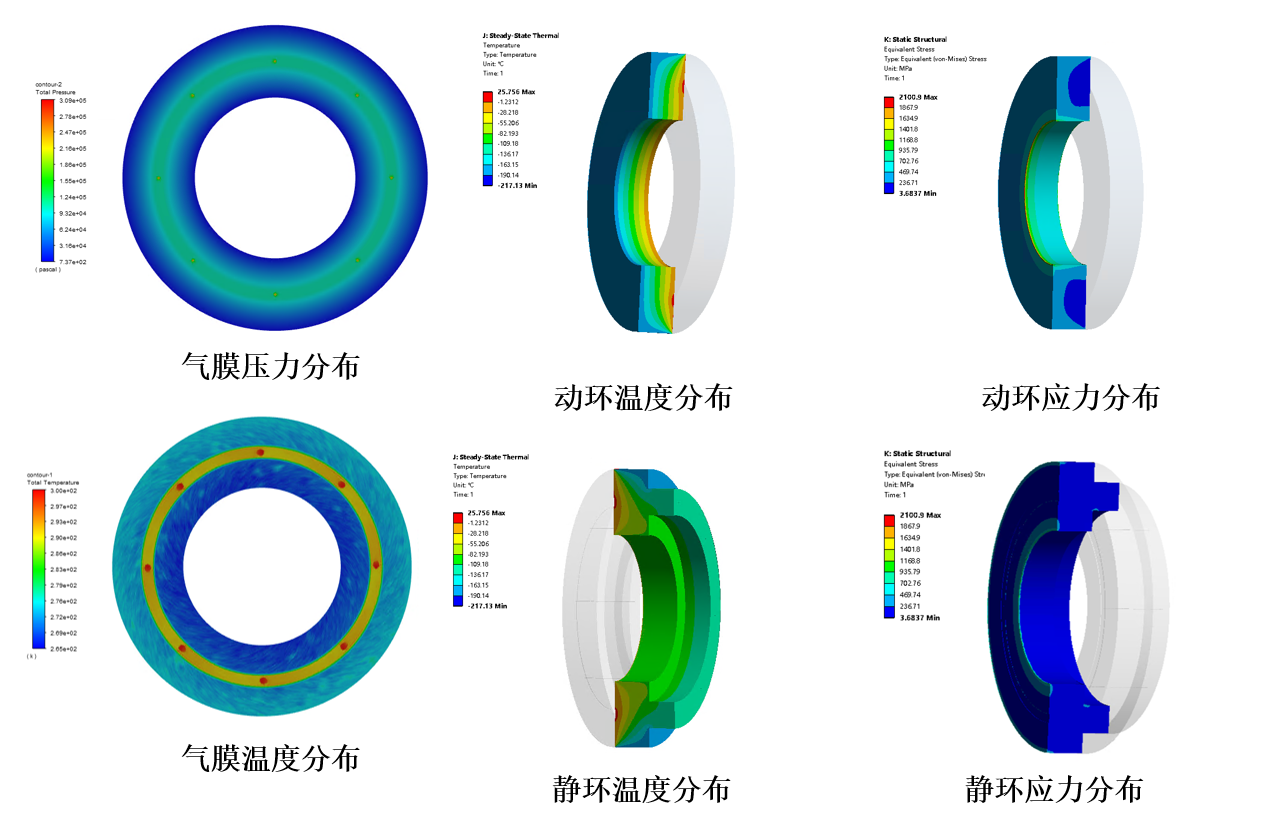

(2)Research on Dynamic Pressure Sealing Technology of Low Temperature Liquid Fuel Medium Turbopump

The dynamic pressure mechanical seal has the characteristics of low wear, long life and self-adaptation to solve the problems such as serious wear and end vaporization of low temperature liquid hydrogen turbopump seal. Using the fluid-solid thermal coupling analysis method combined with parametric design, it provides reference and guidance for the analysis and optimization of the actual working state of the seal, and promotes the engineering application of the dynamic pressure low-temperature seal.

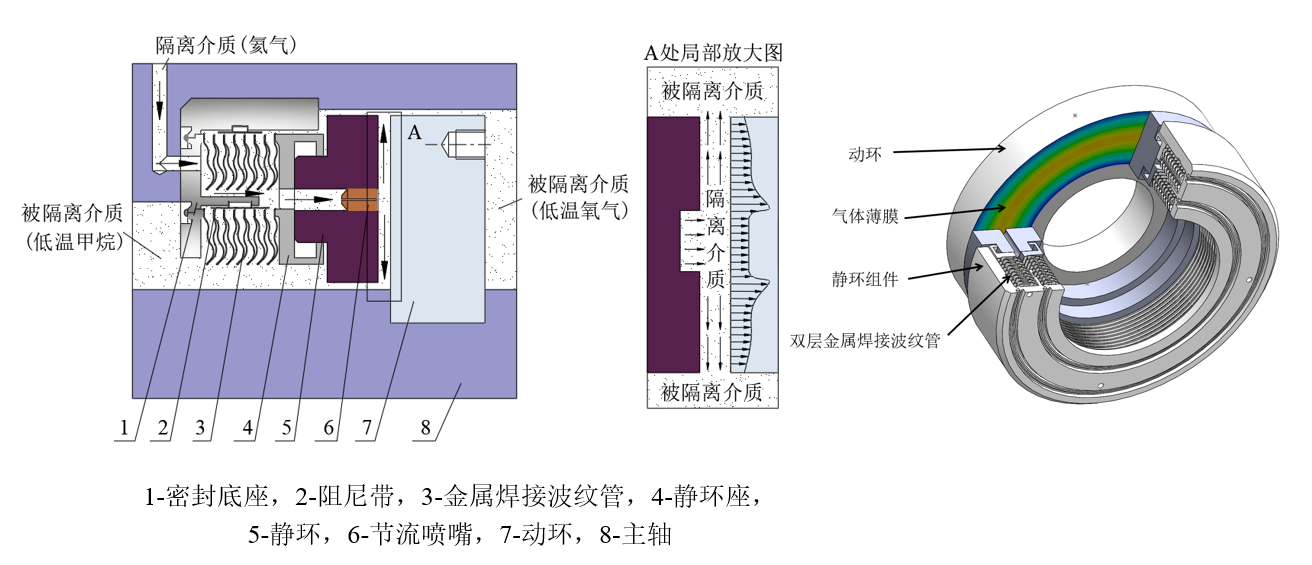

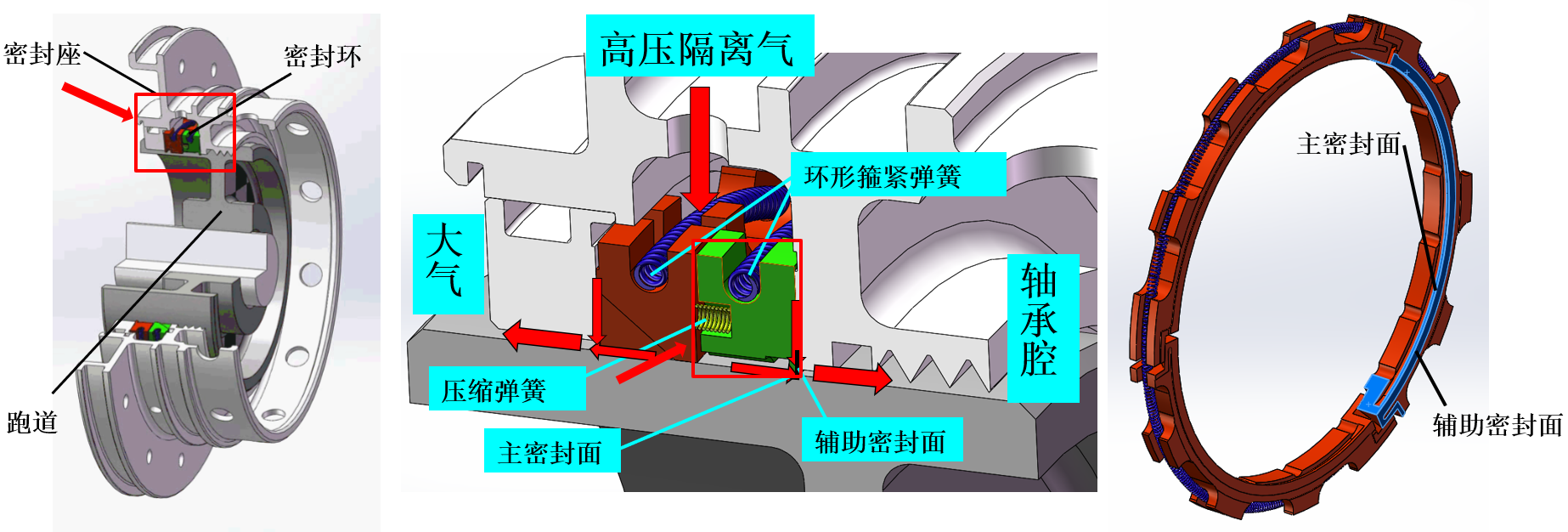

(3)Research on Isolation Gas Seal Technology for Turbopump

A new type of static pressure isolation seal for oxygen pump and fuel pump is developed. The lubrication mechanism of static pressure gas between seal ends is investigated, the variation rule of static pressure isolation seal performance is analyzed, and the seal design method is summarized. It provides research basis and theoretical support for the production of static pressure isolation seals with long life, high stability and high reliability.

2. Aviation Sealing Technology

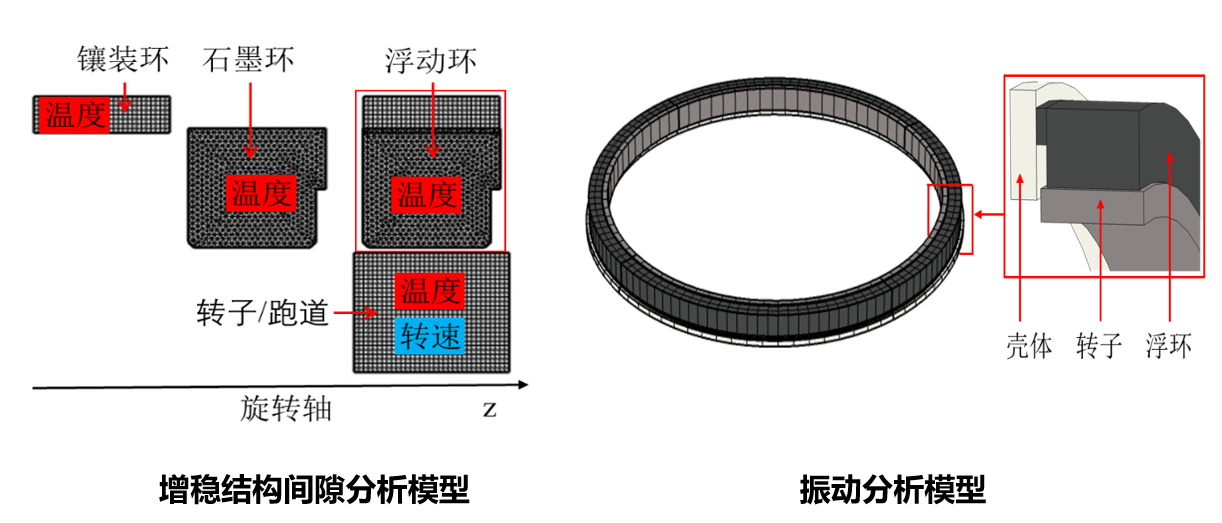

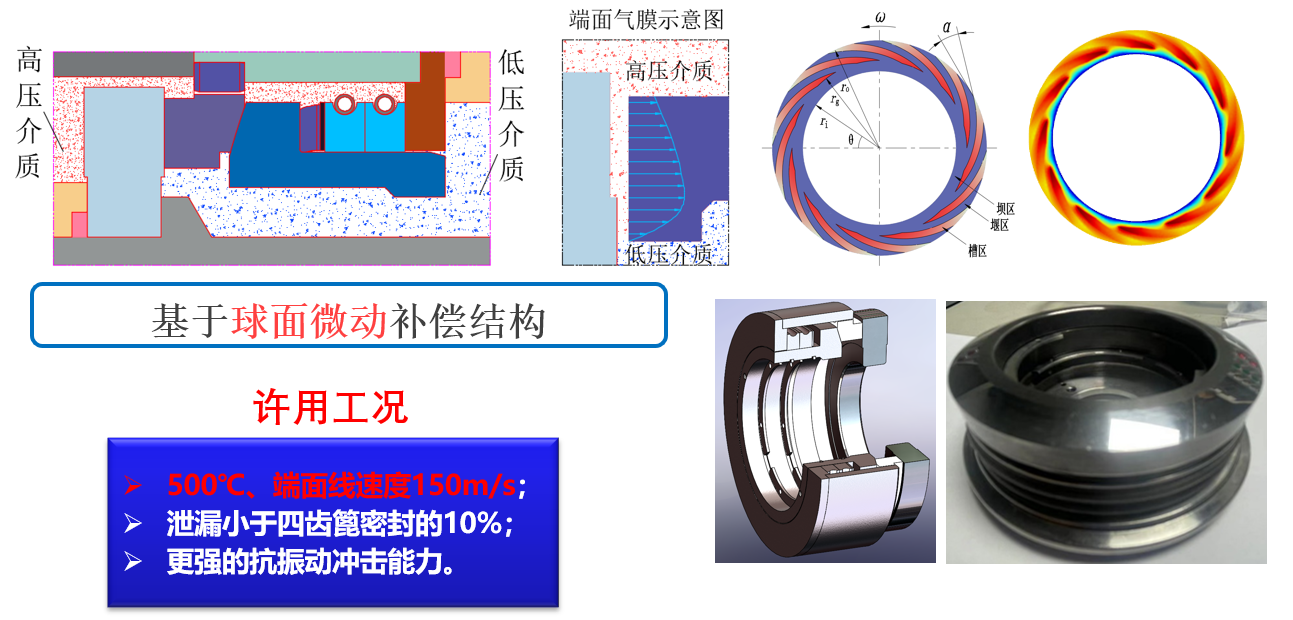

(1)Research on the Design and Performance Analysis Technology of High Reliability Floating Ring Seal Structure under High Parameter Operating Conditions

In view of the problems of large eccentricity, poor stability, weak anti-vibration and impact ability and insufficient reliability of the floating ring graphite seal used in the bearing chamber of aeroengine under high temperature and high speed conditions, the structural design and life evaluation of the floating ring graphite seal with high stability under high parameter conditions were carried out. The structural design method and performance analysis technology of the highly reliable floating ring graphite seal under high parameter conditions are developed, which provides a more accurate prediction of the working life of the floating ring seal, and provides theoretical and experimental support for the design of the floating ring graphite seal under high temperature conditions and high stability.

(2)Research on Circular Sealing Technology of Aircraft Engine Bearing Chamber

In order to solve the problems of low stability, low vibration resistance and low reliability of circular seal used in aero-engine bearing chamber under high temperature and high speed conditions, the research of circular seal with high stability under high parameter conditions was carried out. The function mechanism of circular seal under high parameter working condition was investigated, the variation rule of circular seal performance was analyzed, and the design method of circular seal was summarized. It provides research basis and theoretical support for the production of circular seals with long life, high stability and high reliability.

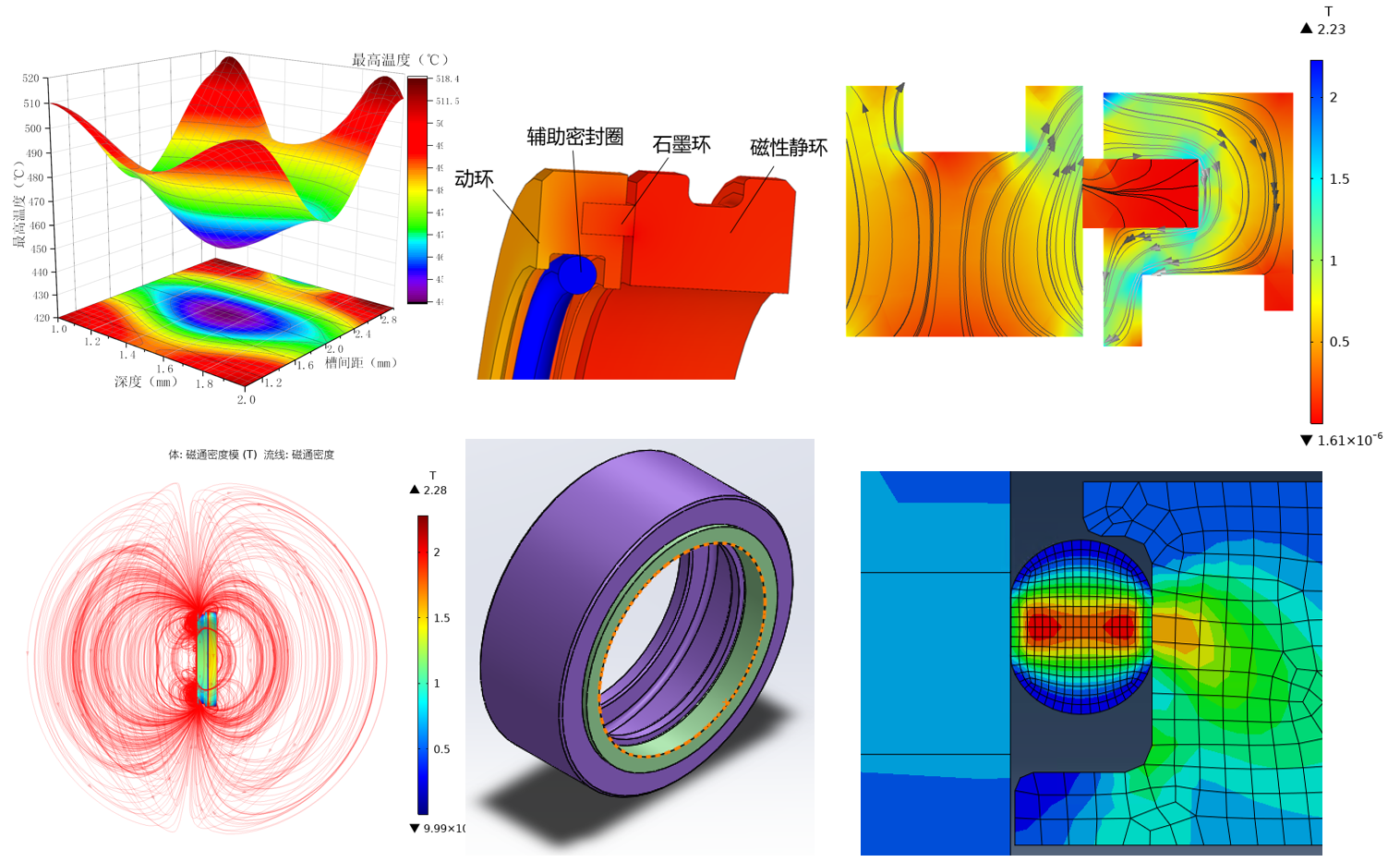

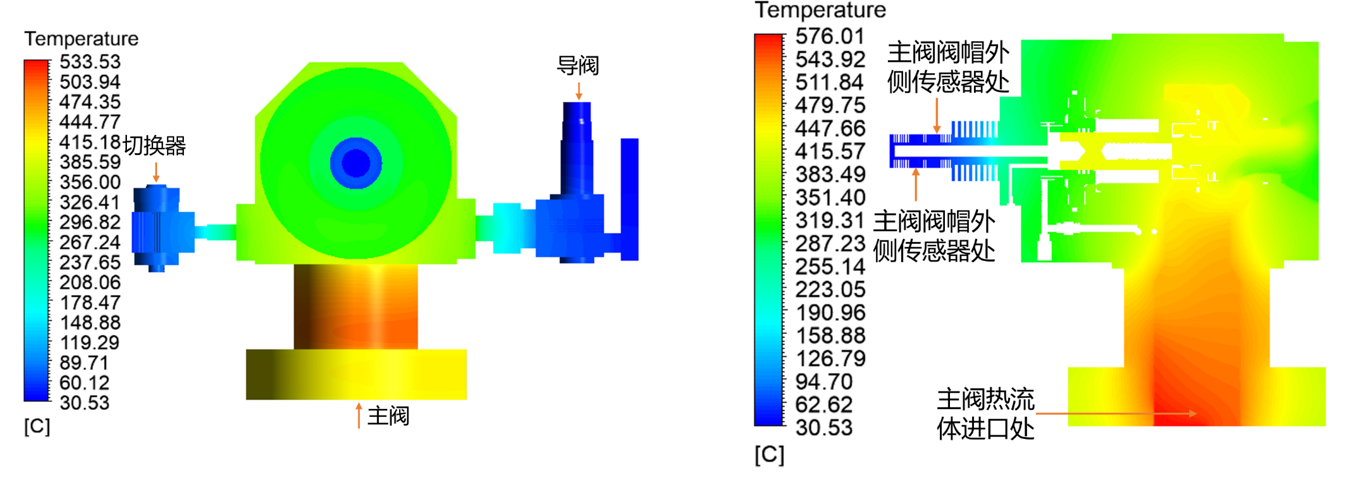

(3)Development and research of ultra-low leakage magnetic sealing device

Aiming at the problems of poor stability, weak resistance to vibration and shock and insufficient reliability of aero-engine under high temperature and high speed conditions, the research of high stability magnetic seal technology under high parameter conditions was carried out. The mechanism of the magnetic seal under high parameter conditions is explored, and the magnetic force is used to replace the elastic force, so that the sealing device can obtain enough pressing force. The compensation force provided by the magnetic force makes the mutual following of the dynamic and static rings better, the end face is higher, and the friction and wear are less. At the same time, the structure of the magnetic seal device is simpler, and it is suitable for the occasions with smaller installation space.

(4)High temperature and long-life shallow groove dynamic pressure sealing technology

The effects of high temperature, high pressure and variable speed on the sealing of oil and gas two-phase medium in engine high speed bearing chamber were studied. The shallow groove type dynamic pressure seal is designed to meet the requirements of low leakage, low wear and long life of engine high speed bearing chamber seal. The seal applied to the main bearing cavity of the engine can adapt to the harsh working environment, meet the performance requirements of the next generation aero engine, and improve the overall performance of the aero engine.

3. Ship Sealing Technology

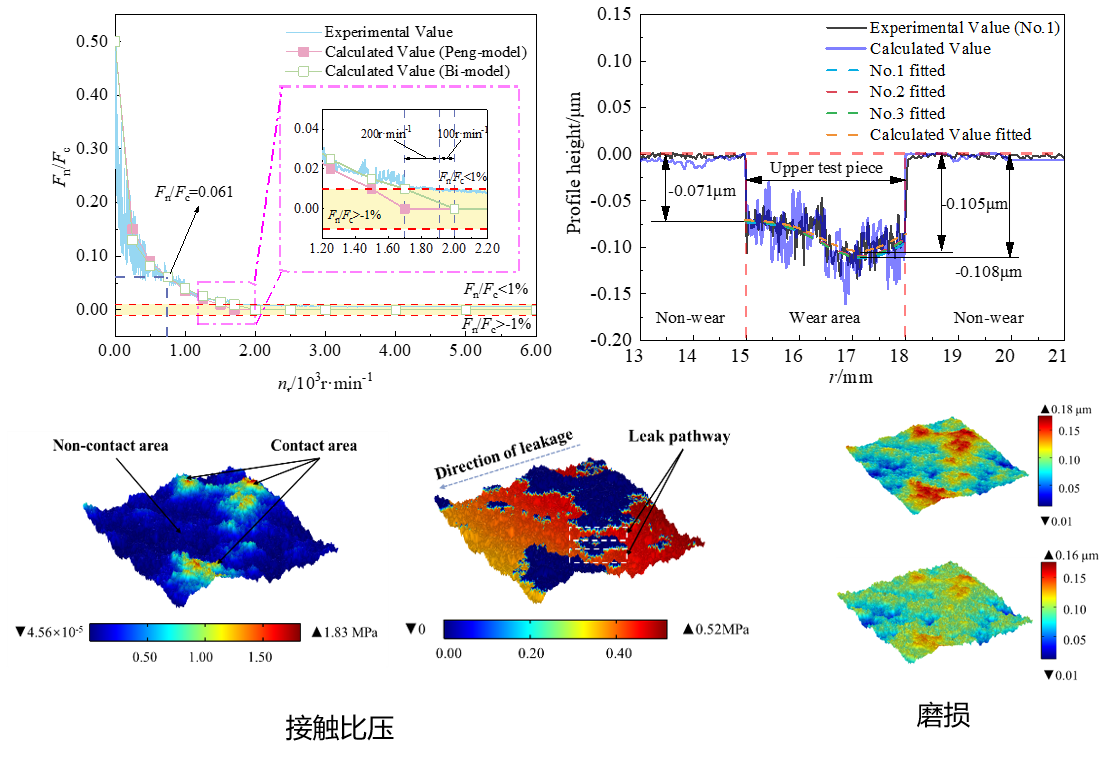

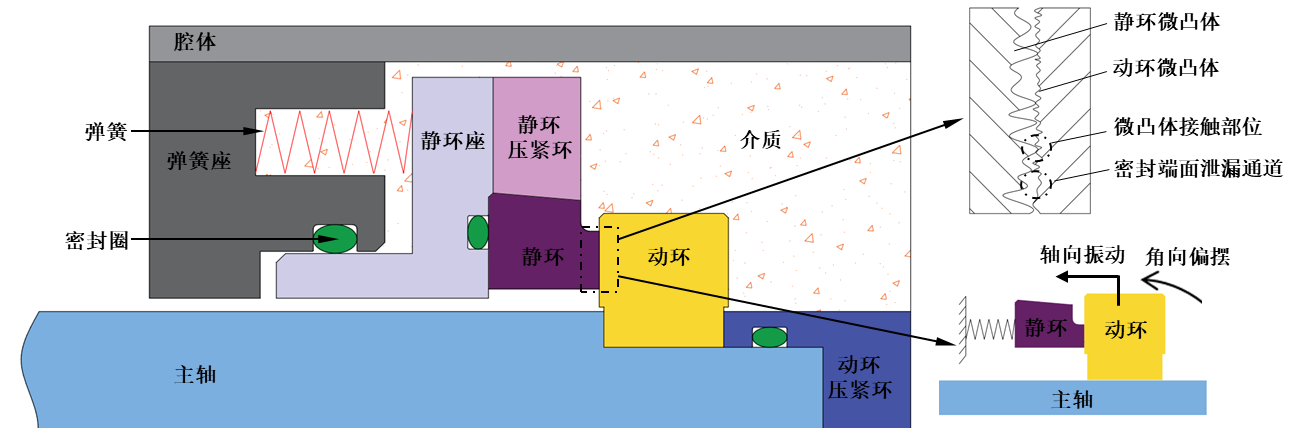

(1)Development and Research of High Pressure and Large Diameter Mechanical Seals for Ships

The mechanical seal performance analysis model of Marine pump is established, and the effect of different parameters on seal performance under variable working conditions is analyzed. The vibration characteristic analysis model of Marine pump mechanical seal is established, and the vibration characteristic of seal is explored, which provides ideas for anti-vibration design of seal. The original seal structure is optimized to achieve high speed, stable and low friction operation of the seal, and to maintain low leakage, greatly improving the reliability and operation efficiency of the ship.

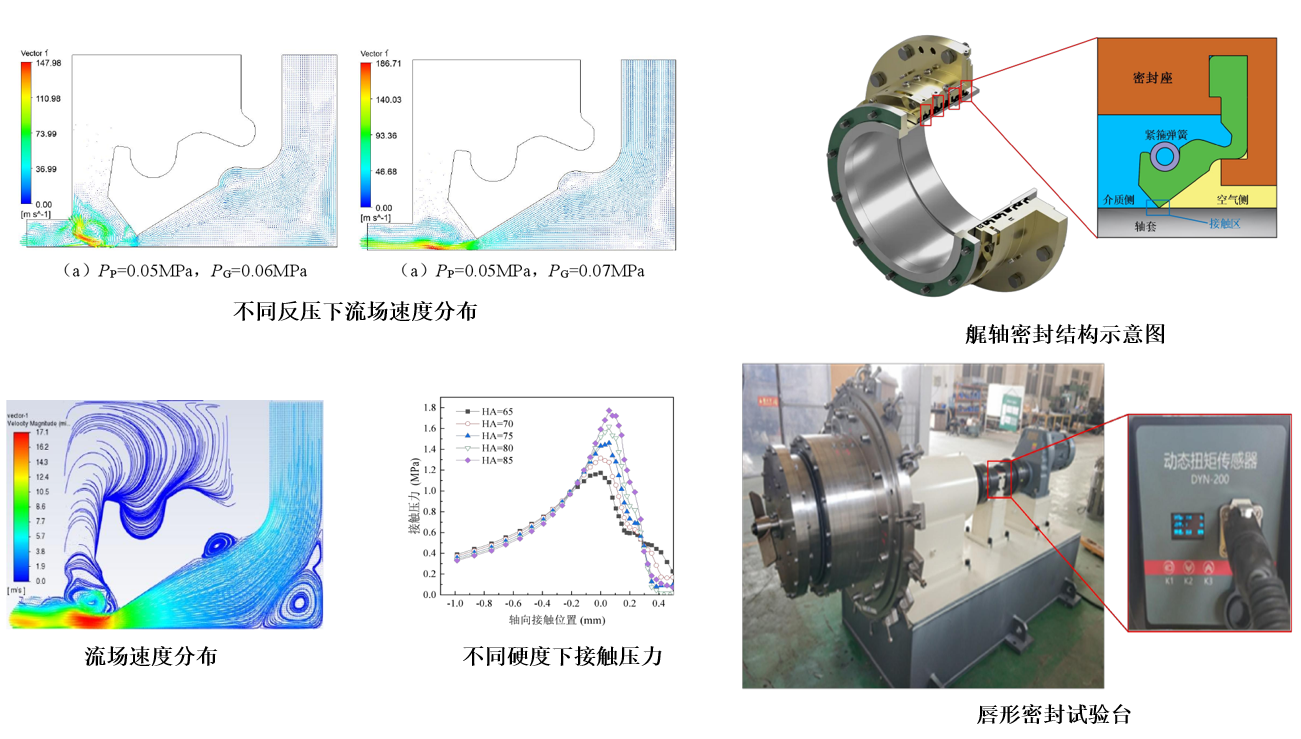

(2)Ship stern shaft rotating lip seal

The project studied the fluid-structure coupling effect between the lip seal, seawater and reverse gas flow in the open lip seal assembly, and revealed the action mechanism of the open lip seal contact surface. The characteristics of flow field and gas-liquid field boundary during lip opening were studied to reveal the sealing mechanism of the open lip seal ring, obtain the gas leakage rate under stable opening state, and avoid the long-term friction of lip. The problems of serious wear and large leakage during operation of the original contact seal are solved, and the non-metallic material non-contact dynamic seal of the stern shaft of large ships is realized.

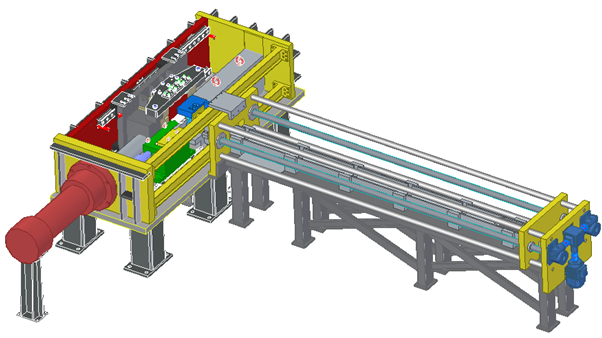

4. Nuclear power plant

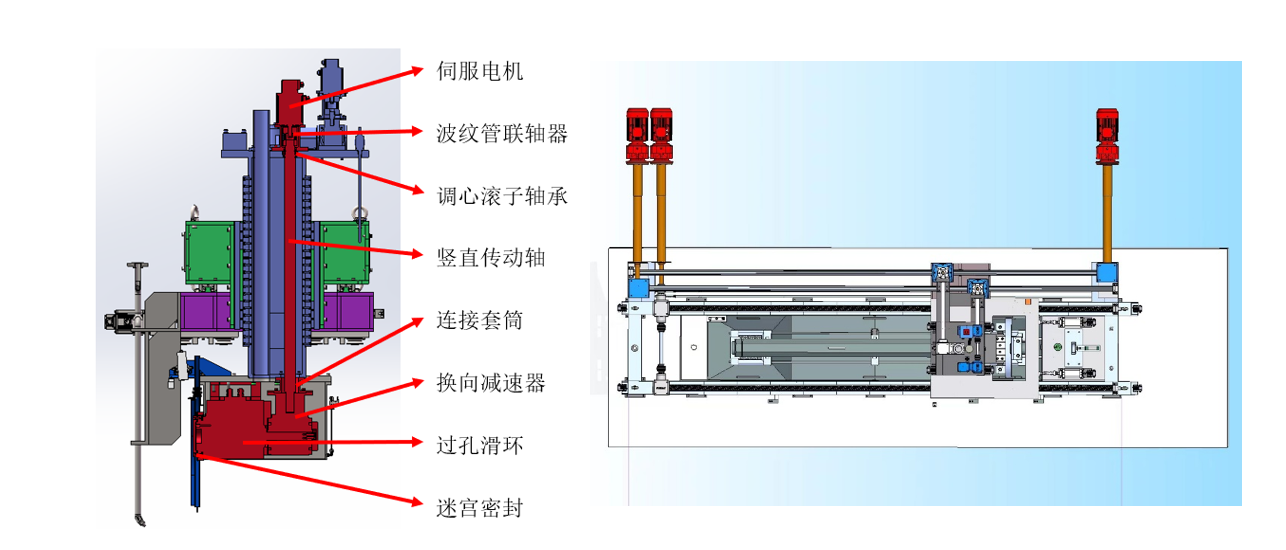

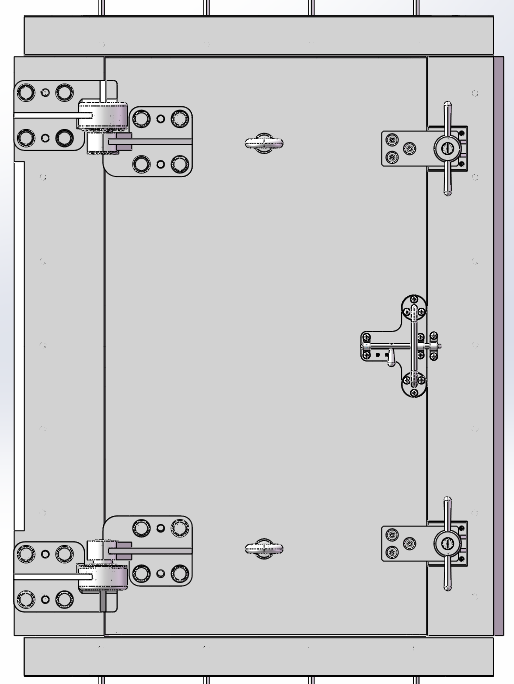

According to the proposed design requirements and main technical parameters, complete the detailed design of the end cutting device prototype compatible with VVER components and K pile (including control system and auxiliary supporting system). The equipment structure, rotary cutting, electric energy system, automatic tool change system, cylinder clamping system, saw blade feed and compression system, factory test equipment and auxiliary system are designed, and relevant important parts should be analyzed and checked during the design process. Detailed design, processing, installation and debugging of end cutting device prototype and supporting devices.

|

|

5. Rubber and plastic soft sealing technology

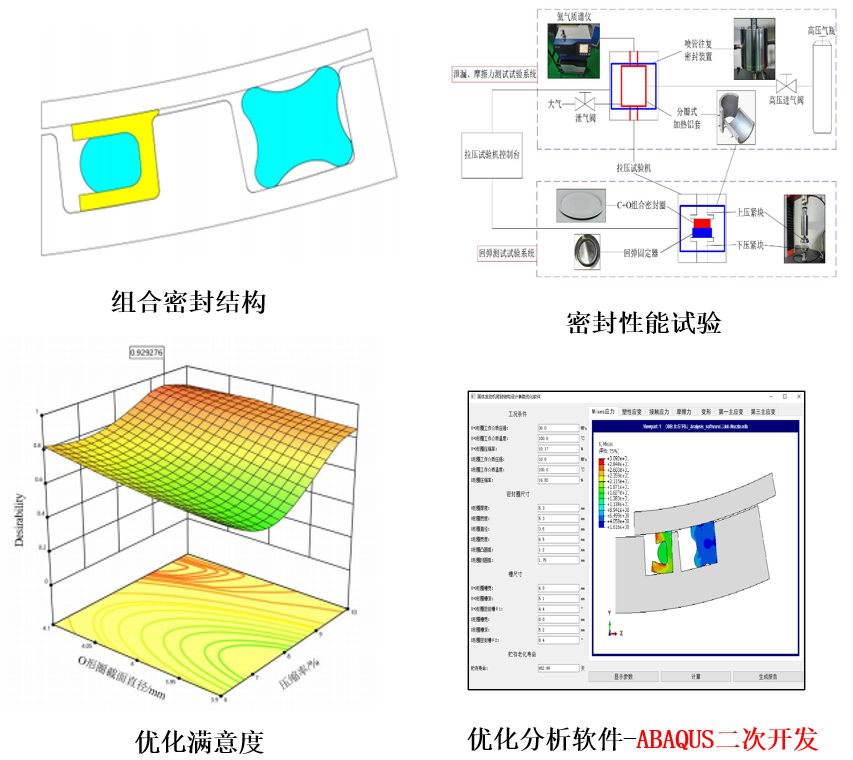

(1)Solid rocket motor nozzle combination seal

By means of numerical analysis and experimental verification, the performance and structure optimization of the combined seal were studied, and the stable seal at high temperature, high pressure and deflection polarization of the engine nozzle was realized.

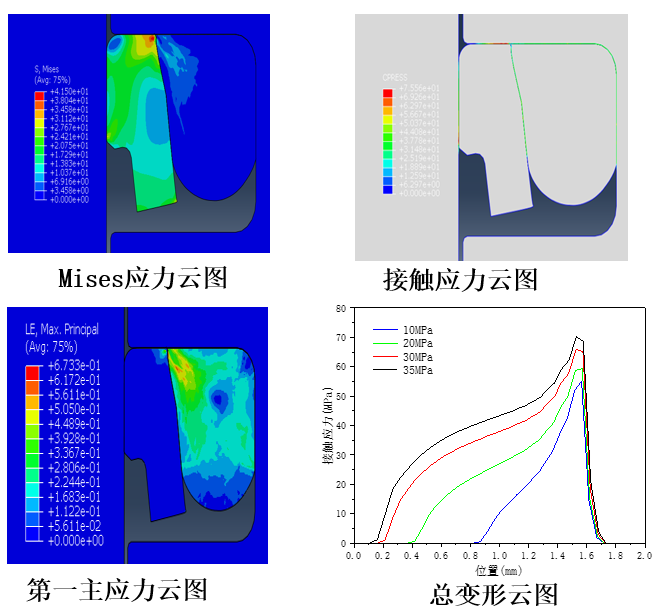

(2)Research on the Performance of Spring Energy Storage Coil

The sealing and wear performance analysis model of the spring energy storage seal ring is established, and the analysis and optimization method of the seal ring performance and wear life prediction method are proposed based on the structural strength, leakage and friction characteristics.

(3)Sturgeon Rubber Composite Seal

The simulation model of the reciprocating seal structure was established, the structure optimization and life prediction of the seal structure were carried out, and the long life, self-compensation and self-lubrication properties of the seal structure were effectively realized.

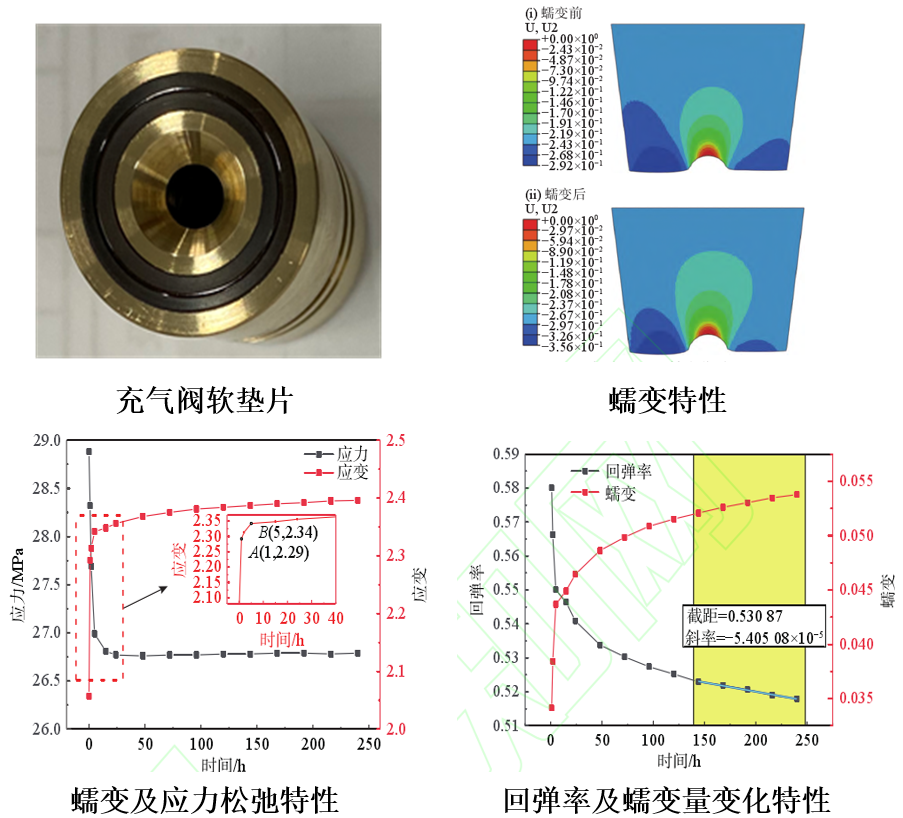

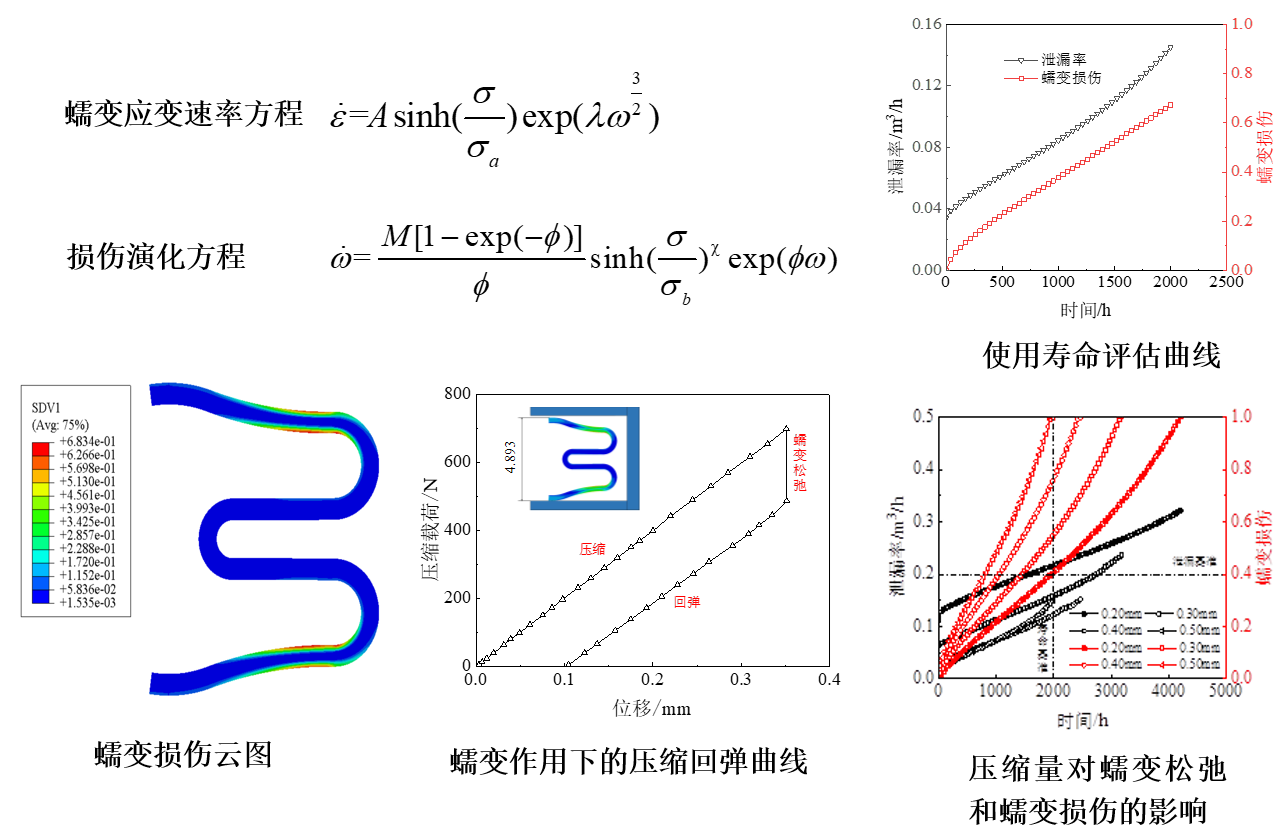

(4)Creep and Life Analysis of FEP Gasket Sealing for Engine Inflation Valve

The creep failure mechanism of soft seals in a wide temperature range was revealed, the effects of different parameters on creep relaxation and life were studied, and the multi-objective structural optimization was carried out using the response surface and particle swarm optimization method to effectively improve the safety and reliability of soft seals in a wide temperature range.

(5)Research on the Performance of Metal W-shaped Sealing Ring

The hyperbolic sinusoidal creep damage model based on continuous damage mechanics describes the creep relaxation and creep damage evolution of W-shaped sealing ring, and predicts the service life.

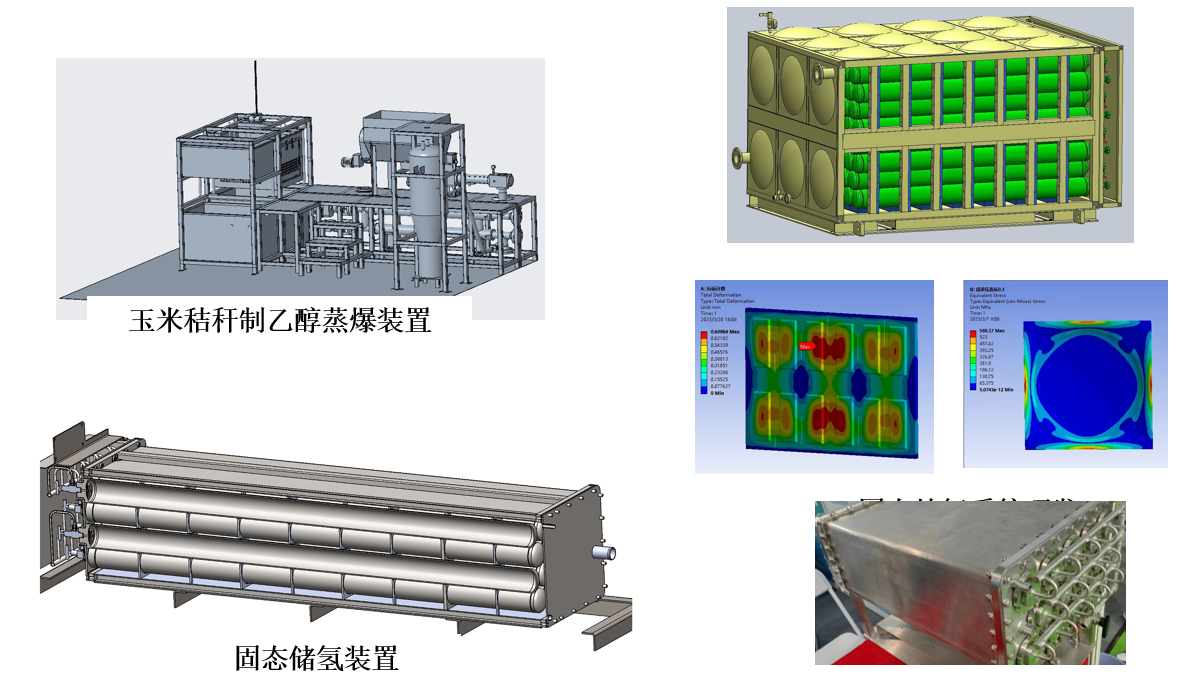

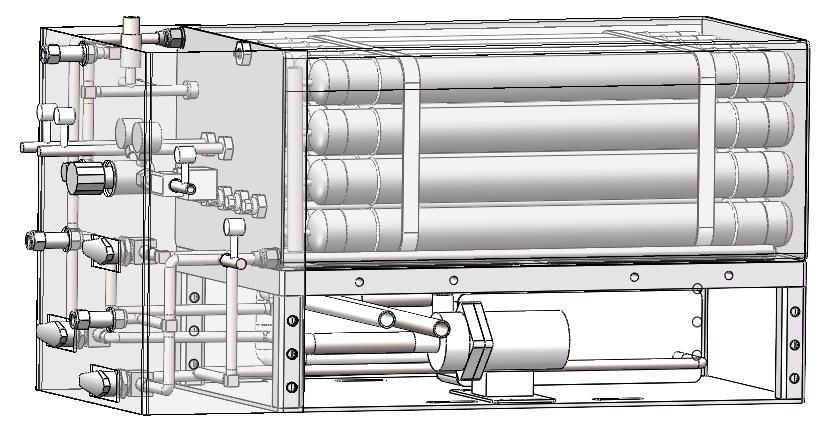

6. Solid state hydrogen storage device

According to the design technical requirements, the solid hydrogen storage device of forklift truck is designed, including the design of the device process flow system, the design of the hydrogen storage device and the design of the external connection pipeline. Developed a large number of hydrogen storage devices, including high pressure hydrogen storage tank, ultra high pressure hydrogenation filter, vehicle solid hydrogen storage device, etc., high safety, drawings successfully accepted and practical successful application. He has rich experience in finite element analysis, and has completed a lot of work such as strength checking calculation, fatigue analysis, heat transfer analysis and seismic analysis of pressure vessels.

|

|

|

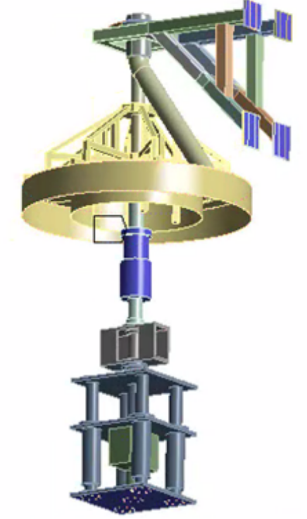

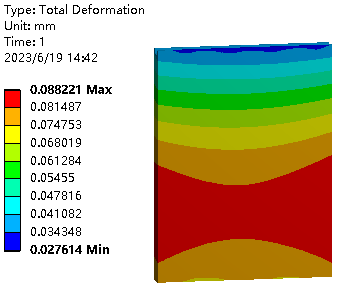

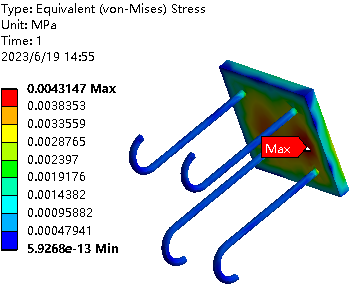

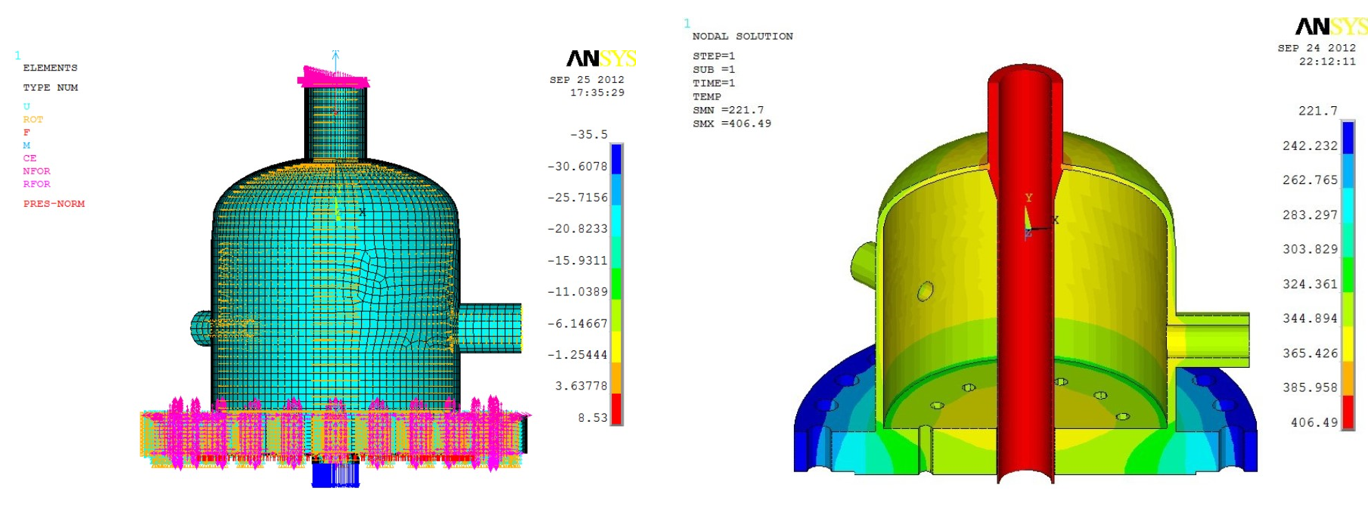

7. Seismic analysis of nuclear power plants

The finite element software ANSYS is used to calculate the load of nuclear power equipment under earthquake conditions, and its strength is analyzed. According to the requirements, the finite element seismic analysis is carried out on the structure. According to the analysis results, it can be seen that the structure of nuclear power equipment meets the relevant seismic design requirements under earthquake conditions.

|

|

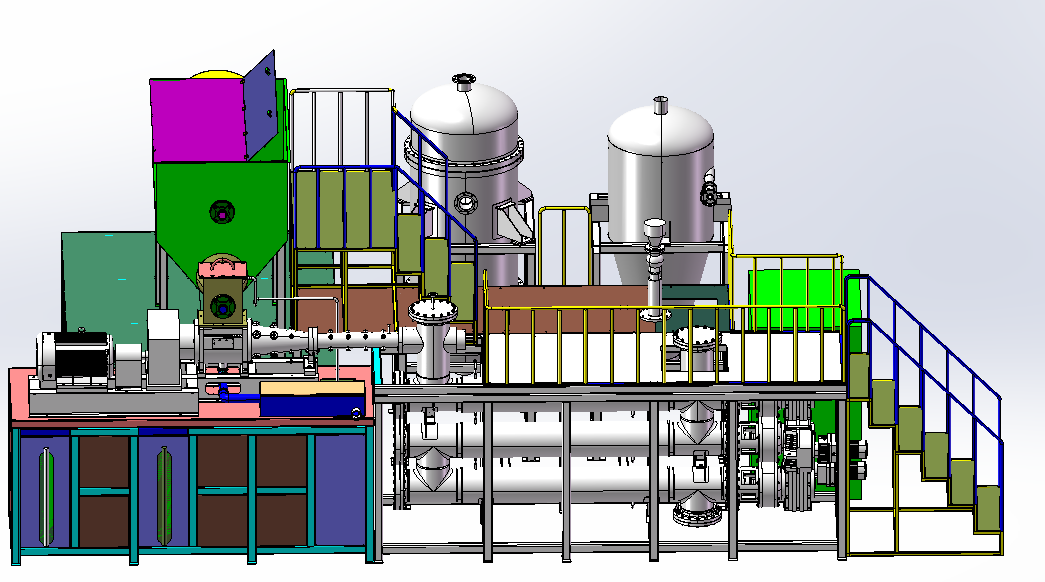

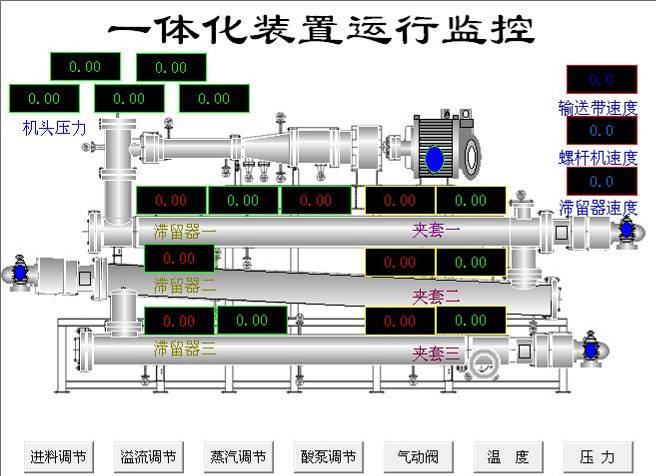

8. Pre treatment of straw steaming and explosion

The 100-ton fuel ethanol integrated screw straw steam explosion device is a straw pretreatment device, which integrates the functions of kneading, crushing, dewatering, pressurizing, counter-pressurizing and blasting of corn straw. The integrated continuous steam explosion device jointly developed with Sinopec Company can simultaneously achieve straw feed impregnation and dehydration, prevent the impregnated straw from slipping off during transportation, crush and fine straw technology, screw extrusion straw feed to form high pressure material seal to prevent steam blowout, and real-time monitoring technology of material seal. Obtained a number of patent achievements.

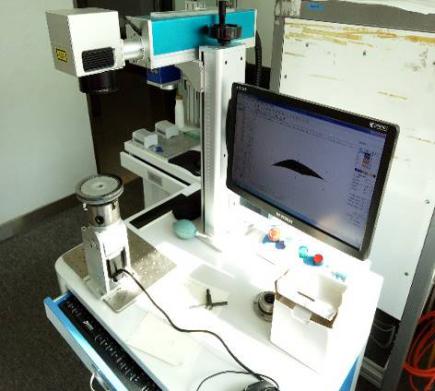

9. Experimental apparatus and control system

The project team has carried out a large number of performance tests of different types of seals, has a complete functional seal test system, mastered the measurement methods for different seal performance parameters, can independently carry out ultra-precision laser machining of shallow groove structure, carried out tribological performance tests of friction pairs, and completed 2000h durability tests of seals.

|

| |

(a)Low speed sealing test bench | (b)High speed sealing test bench | |

|

| |

(c)High pressure compressor | (d)High pressure gas storage system | |

|

| |

(e) Sealed leakage measuring device | (f) Digital laser sealing end face processing system | |

|

| |

(g) High precision flatness measuring instrument | (h) Material micro texture measurement device | |

|

| |

(i) Laboratory integrated control system | (j) Self-developed sealing control software | |

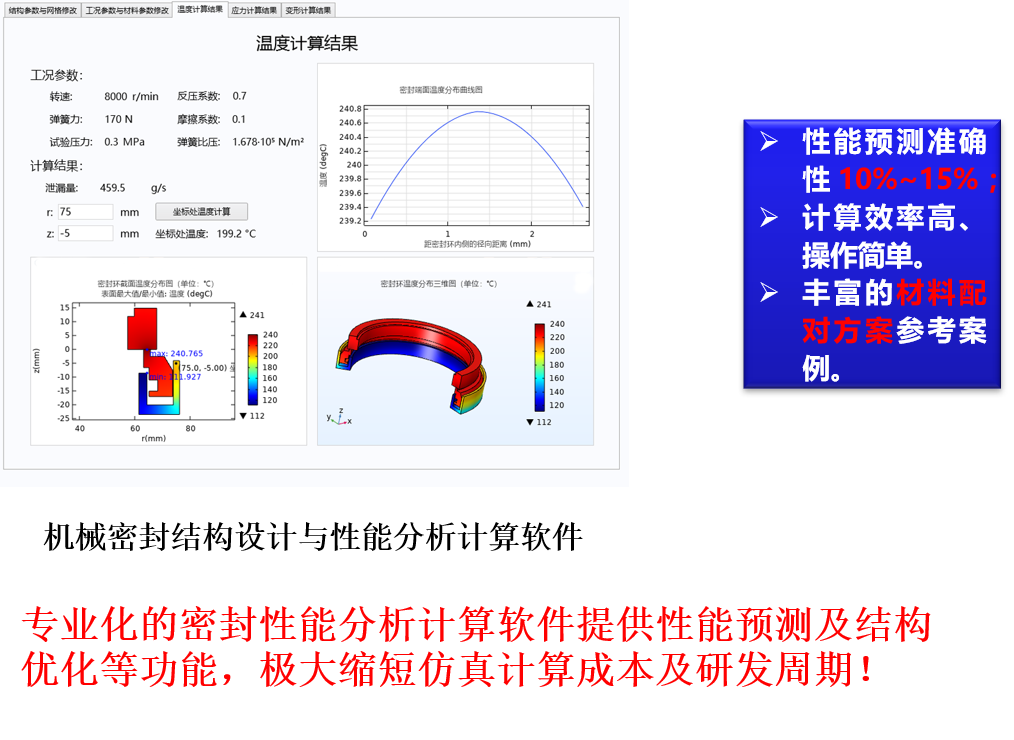

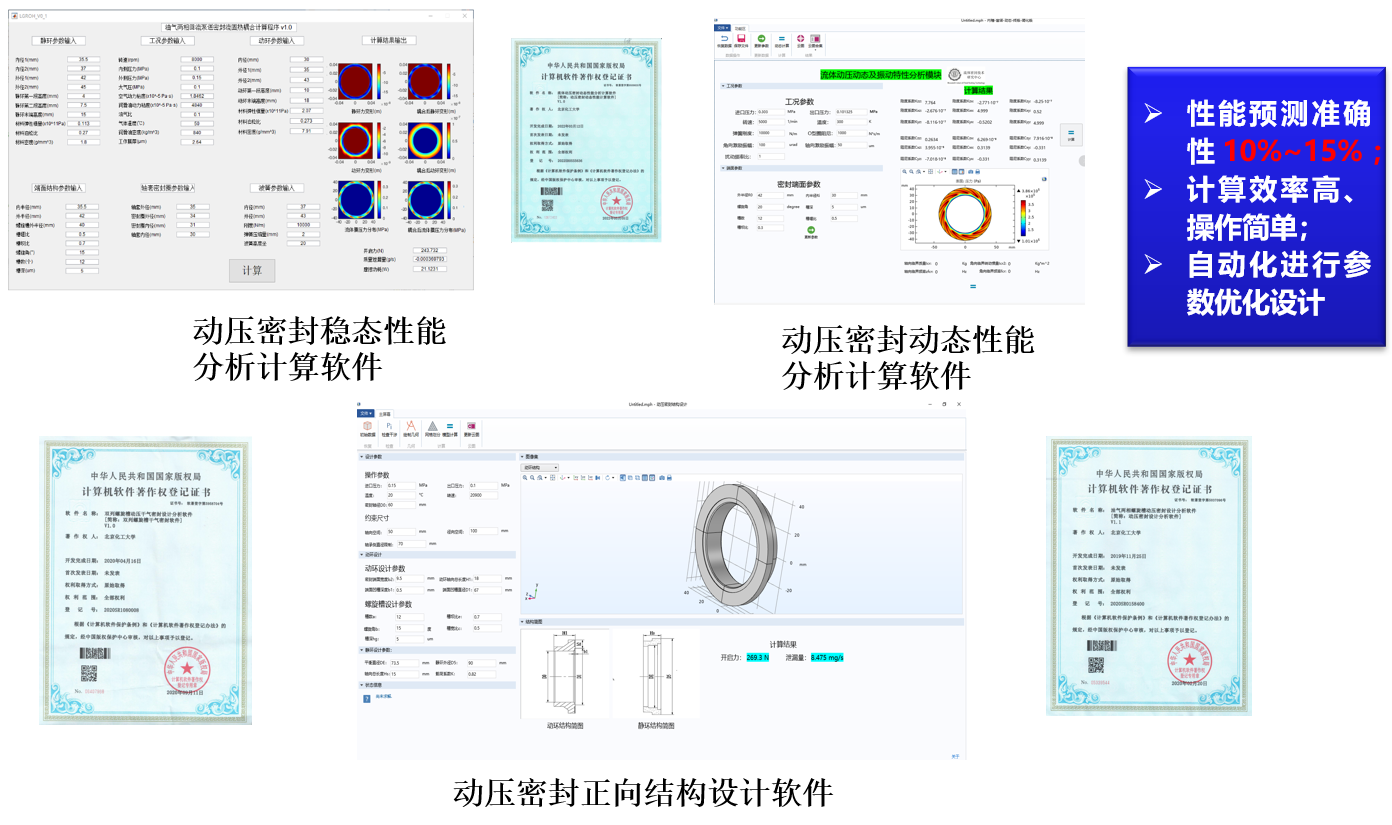

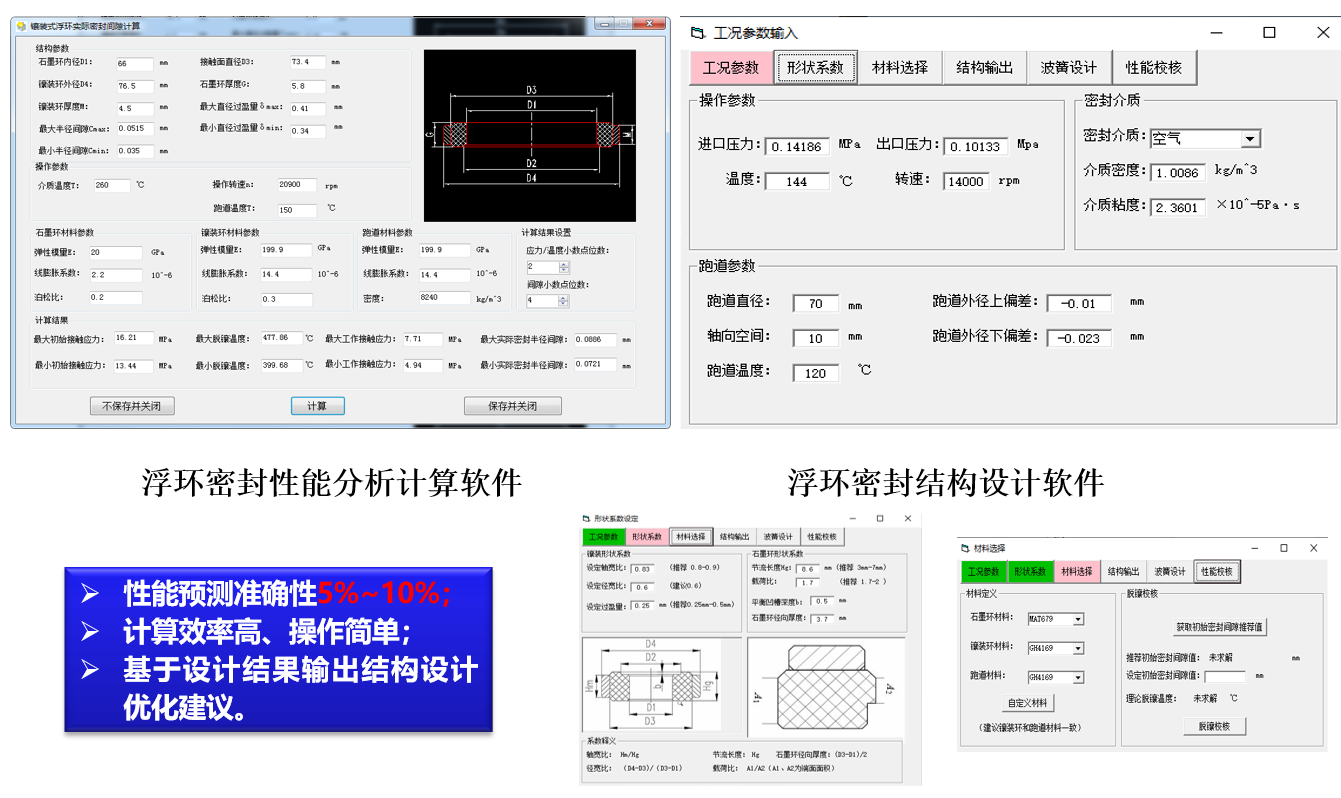

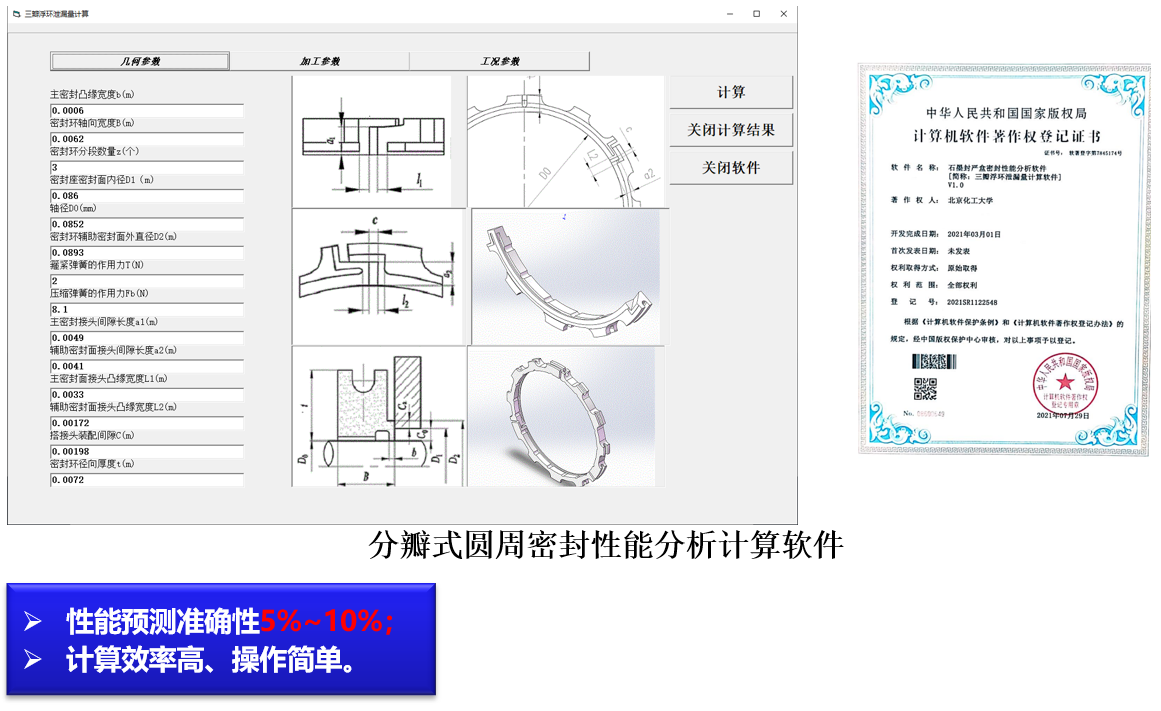

10. Intelligent analysis structure design software platform

The team independently developed a variety of fluid seal calculation, analysis and design software.

(1)Dynamic pressure seal structure design and performance analysis calculation software

(2)Floating ring seal structure design and performance analysis calculation software

(3)The software of structure design and performance analysis and calculation of split circular seal

(4)High speed mechanical seal structure design and performance analysis and calculation software