(1)Technology and Equipment for Precise Extrusion

The precision polymer extrusion technology and equipment have been widely applied and industrialized across multiple sectors. This achievement has been massively commercialized by leading industry players such as Ningbo Haitian Group and Weifang Kaida Plastic Machinery Co., Ltd., generating significant economic and social benefits. As a result, the technology was awarded the 2nd Prize of the National Science and Technology Progress Award in 2011.

In collaboration with Weifang Kaida Plastic Machinery Co., Ltd., the high-speed polymer extrusion technology and equipment that were co-developed have also been successfully industrialized on a large scale, bringing about remarkable economic and social impacts. This collaborative achievement was recognized with the 1st Prize of the China Machinery Industry Federation Science and Technology Progress Award in 2014.

(2)High-Filled Green Composite Materials Molding Technology

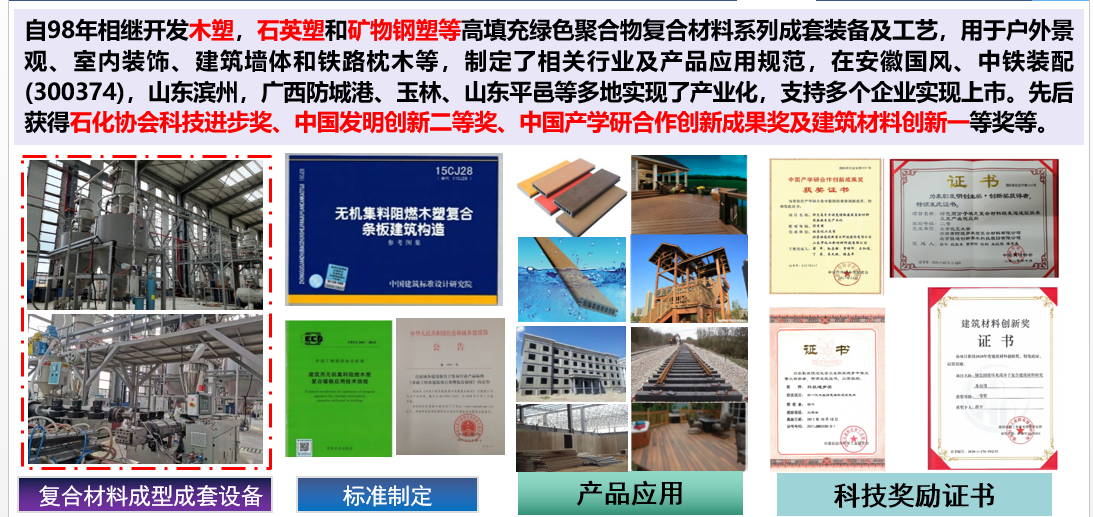

Since 1998, a series of complete sets of equipment and processes for high-filled green polymer composite materials, including wood-plastic, quartz-plastic, and mineral-plastic composites, have been developed successively. These materials are used for outdoor landscaping, interior decoration, building walls, railway sleepers, and other applications. Industry and product application standards have also been formulated.

The industrialization of these green composite materials has been achieved in multiple locations, including Anhui Guofeng, China Railway Assembly (300374), Shandong Bin zhou, Guangxi Fangchenggang, Yulin, and Shandong Pingyi, supporting several enterprises to achieve public listings.

These achievements have been recognized with prestigious awards, including the Petrochemical Association Science and Technology Progress Award, the China Invention and Innovation 2nd Prize, the China Industry-University-Research Cooperation Innovation Achievement Award, and the 1st Prize of the Building Materials Innovation Award.

This comprehensive technology platform for high-filled green polymer composites has enabled the development of cost-effective, environmentally-friendly materials that have been widely adopted across diverse industrial applications, contributing to the sustainable growth of the polymer industry.

(3)Polymer Supercritical Fluid Extrusion Foaming Technology

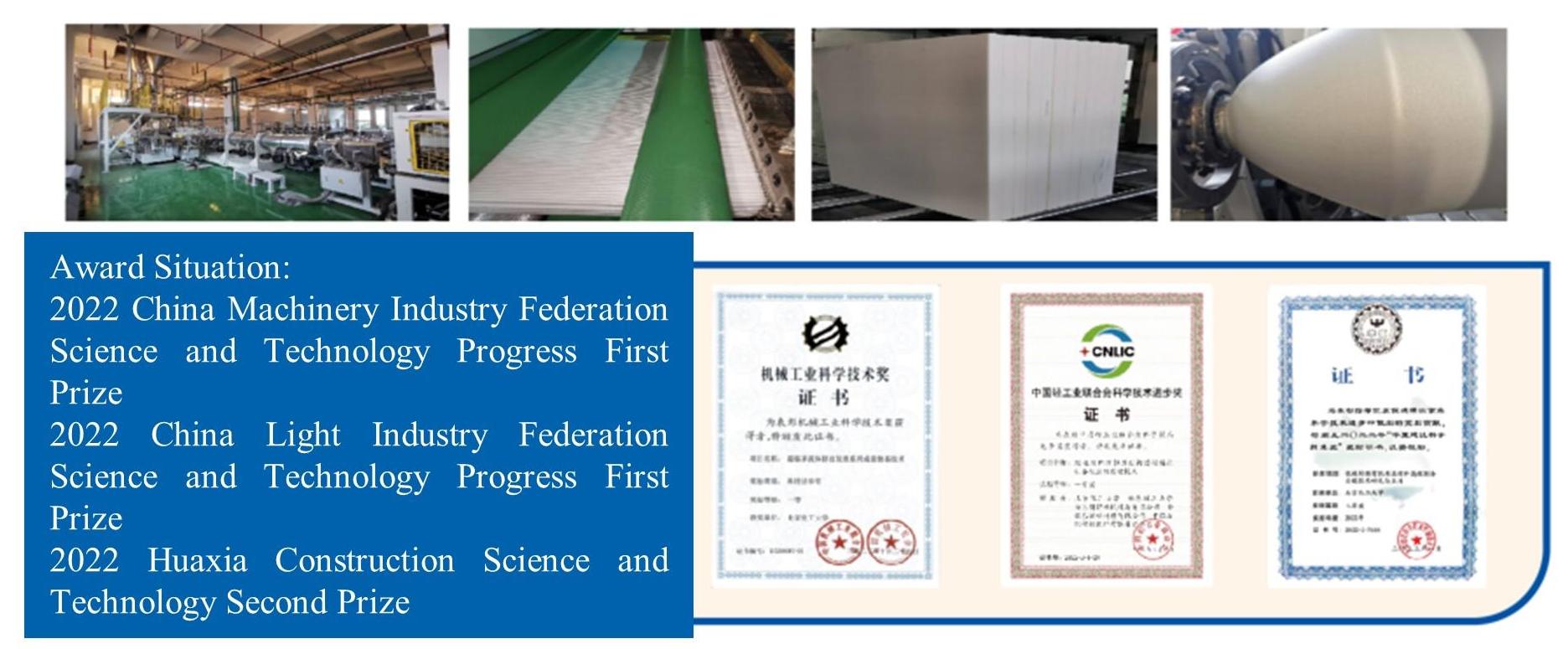

Polyethylene terephthalate (PET) Dry-Free Reactive Foaming Technology, PET foam core materials have broad applications in the fields of wind turbine blades, automotive interior and exterior, construction materials, high-speed rail, shipbuilding, and logistics packaging. The production technology for these materials was monopolized by developed countries prior to 2019. Through collaboration with Nanjing Chuangbo, the North China University of Technology Plastic Machinery Institute has achieved breakthroughs from the laboratory to pilot-scale and industrial production of PET foam core material manufacturing technology, becoming the first in China to realize mass production capabilities for this technology. They have also continuously developed a series of products suitable for various application scenarios.

The institute has successively received the First Prize for Science and Technology Progress from the China Machinery Industry Federation in 2022, the First Prize for Science and Technology Progress from the China National Light Industry Council in 2022, and the Second Prize for Science and Technology Progress from the China Construction Science and Technology Association in 2022.