(1) Polymer-matrix advanced materials preparation technology and equipment

(2) Polymer product molding, processing and advanced manufacturing, injection molding, extrusion molding, rotary molding, compound molding and magnetic spinning.

(3) Polymer molding and processing CAD/CAE/CAM

(4) High-efficient energy utilization and new energy-saving and emission-reduction technology

Main Research Areas of Tire Design and Manufacturing Process

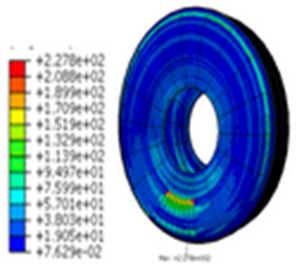

Focusing on "tire performance dynamic simulation design theory", establish an industry-leading tire R&D system integrating design, simulation, optimization and test. Carry out tire-vehicle matching research, computer 3D finite element mechanics ****ysis, design optimization and performance prediction, tire tread and noise research, and build up a high-performance radial tire development system holographic data sharing platform.

Carry out study on tire material performance parameter, mechanical performance parameter testing condition building and non-linear relationship description method, establish a database for key tire materials, and lay a foundation for tire performance simulation and digital manufacture.

Break the "bottleneck" that constrains the development of the tire rubber processing industry of China, namely, the low efficiency of conventional high-temperature multiple mixing, unstable performance of rubber and high energy consumption of rubber making, so as to form a low-temperature rubber mixing process (TMS) for the industry.

Independently develop key technology for super-sized engineering radial tires and military tires, independently develops 57' and 63' super-sized engineering radial tire and military bullet-proof products, and achieve serial industrial production, break international monopoly and fill in the gap.

Form 3-5 innovative tire formula design techniques, develop the tire tread formula with high wear-resisting, wet-skid resisting and low heat-generating features, and realize fuel saving by 3-5%.

Carry out nano micro-layer airtight rubber manufacturing technology research, develop new airtight tire materials to replace high-energy-consuming halogenated butyl rubber, establish radial tire rolling resistance testing equipment and testing method, and build up experiment testing capacity which can be shared in the industry.

(2) Polymer product molding, processing and advanced manufacturing, injection molding, extrusion molding, rotary molding, compound molding and magnetic spinning.

(3) Polymer molding and processing CAD/CAE/CAM

(4) High-efficient energy utilization and new energy-saving and emission-reduction technology

Main Research Areas of Tire Design and Manufacturing Process

Focusing on "tire performance dynamic simulation design theory", establish an industry-leading tire R&D system integrating design, simulation, optimization and test. Carry out tire-vehicle matching research, computer 3D finite element mechanics ****ysis, design optimization and performance prediction, tire tread and noise research, and build up a high-performance radial tire development system holographic data sharing platform.

Carry out study on tire material performance parameter, mechanical performance parameter testing condition building and non-linear relationship description method, establish a database for key tire materials, and lay a foundation for tire performance simulation and digital manufacture.

Break the "bottleneck" that constrains the development of the tire rubber processing industry of China, namely, the low efficiency of conventional high-temperature multiple mixing, unstable performance of rubber and high energy consumption of rubber making, so as to form a low-temperature rubber mixing process (TMS) for the industry.

Independently develop key technology for super-sized engineering radial tires and military tires, independently develops 57' and 63' super-sized engineering radial tire and military bullet-proof products, and achieve serial industrial production, break international monopoly and fill in the gap.

Form 3-5 innovative tire formula design techniques, develop the tire tread formula with high wear-resisting, wet-skid resisting and low heat-generating features, and realize fuel saving by 3-5%.

Carry out nano micro-layer airtight rubber manufacturing technology research, develop new airtight tire materials to replace high-energy-consuming halogenated butyl rubber, establish radial tire rolling resistance testing equipment and testing method, and build up experiment testing capacity which can be shared in the industry.

1. Dual-steel ring radial aircraft tires

2. Key technology and equipment for super-sized tire super-wide rubber tire extrusion and molding